Antique rapier, during treatment

When metal becomes corroded, the alloy has undergone a chemical reaction with its environment, typically with oxygen and moisture, which leads to the deterioration of the metal's surface. Improper storage, the age and materials used to make the sword, climate conditions, and lack of consistent proper maintenance can all contribute to metal corrosion, such as with these four antique swords.

Civil War Saber, before treatment

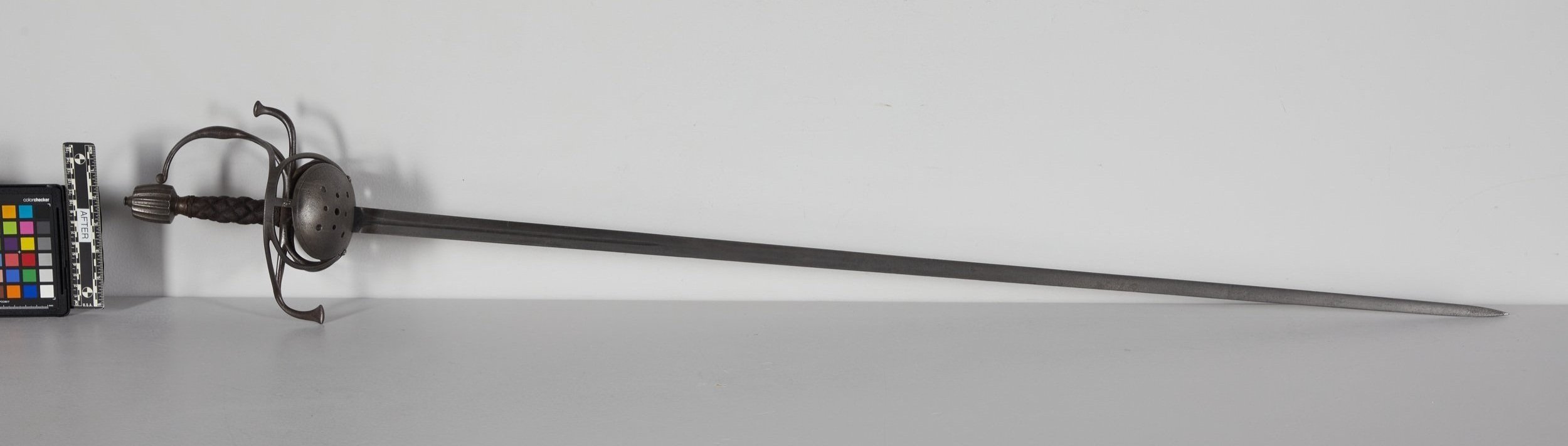

Antique Rapier, before treatment (1/2)

Antique Broadsword, before treatment

Antique Rapier, before treatment (2/2)

Upon arrival at The Center, these four swords - an antique broadsword, two antique rapiers, and a Civil War Saber complete with sheath - all exhibited heavy corrosion. The Civil War saber with sheath had additional condition issues in addition to surface corrosion. The brass hilt, scabbard fittings, and braided wire around the handle were also heavily oxidized. The hilt and pommel were loose, and there were areas of loss to the sharkskin grip. Also, the bottom four inches of the brass scabbard tip were missing.

Antique Rapier, before treatment (1/2) detail

Antique Rapier, after treatment (1/2) detail

Antique Broadsword, before treatment, detail

Antique Rapier, before treatment (2/2), detail

Antique Broadsword, after treatment, detail

Antique Rapier, after treatment (2/2), detail

Senior Conservators of Furniture Stephen Ryan took on the task of conserving this sword collection. To remove the metal corrosion, the swords were cleaned using electrolysis. The electrolysis process involves placing the metal in a weak alkaline solution. Then, a low electric current is run through the solution. A battery charger was attached to the blade and the other to a sacrificial anode (a piece of steel), removing the rust from the blade. It is essential that this is only performed by an experienced professional; if the process is executed incorrectly, more damage will be caused to the metal.

Metal before electrolysis

Metal after electrolysis

The technique left the blades corrosion-free, allowing them to be re-patinated. The re-patination process is the intentional recreation of the surface patina, which requires great care and expertise to ensure that the newly created patina matches the age and style of the object while preserving its historical value. The Civil War saber required additional treatment; the oxidation was removed from the brass, which was also re-patinated, and the sharkskin grip was consolidated with conservation-grade adhesives. The hilt and pommel were secured as well.

Civil War Saber, before treatment, detail

Civil War Saber, after treatment, detail

The final step of the treatment was to apply a protective coat of wax to the swords. The wax prevents oxidation, protects from moisture, and enhances the appearance of the metal. Stephen shared about the success of the treatment, "I was very pleased with the way they all turned out, but most especially the smaller antique rapier. All the swords underwent the electrolysis treatment to remove the corrosion, but that sword was the most heavily corroded, with deep pitting in the metal. I made up a wax stick to resemble the color of the metal and used it to fill the pitted surface. Using a hard wax fill also enabled me to buff the surface to an appropriate luster."

Sword detail, before treatment

Sword detail, after treatment

The thorough conservation efforts undertaken by Stephen have restored these four antique swords to their former glory and ensured their preservation for generations to come. Through the detailed processes of electrolysis to remove corrosion, expert re-patination to recreate an authentic surface patina, and the application of protective wax, these swords have been transformed. Their work not only salvaged the historical significance of these blades but also enhanced their aesthetic appeal, allowing these artifacts to continue telling their stories to all who admire them.